Guascor Energy’s Series & RDS: digitalize the efficiency!

The development of new Gas engines for Power Generation applications has always looked for solutions that could offer to the market the maximum efficiency, minimum emissions, highest reliability and lowest maintenance costs. In the last years, Digitalization has appeared on the scene as a crucial contributor to achieve those targets.

Digitalization is a big word that involves many different things. When we think about it applied to industry we normally tend to imagine it in the design, manufacturing, selling, quality assurance processes of the companies but it is not only there but also in the impact that the application of digital tools has in how products can be improved once in field and can be serviced where lies the tremendous transformative value of digitalization.

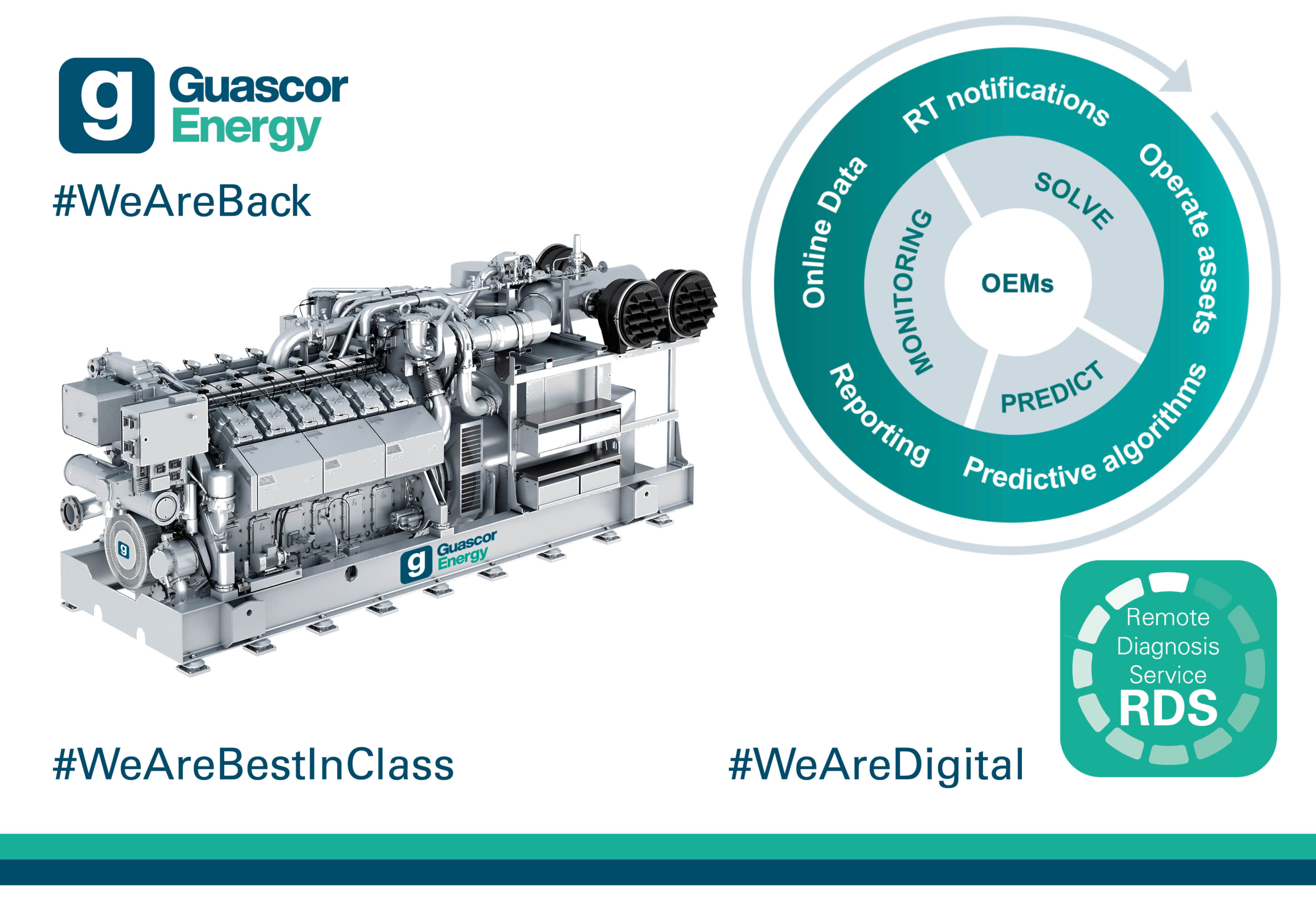

The possibility of accessing the equipment operational parameters (historical or on-line values or alarms), implementing algorithms to detect in advance emerging malfunctions and remotely make changes in the equipment controls has marked a before and after in the product development and service concepts, significantly improving the product validation process, the quality of the reactive support and, last but not least, allowing the capability to offer proactive support to the customer.

As an answer to these needs, Guascor Energy has developed a new field proven best in class in efficiency 2MW engine and a Remote Diagnosis Service tool.

Remote Diagnostic Services (RDS) is based on the OEM expert knowledge, combined with modern tools for analysis, detection and diagnostics to provide to the OEM an essential development tool and to our customers and partners a great and powerful service tool

The application of the RDS in the development and the last available technology in the engine has allowed us to achieve a product with the highest efficiency on the market and the lowest emissions

With two different models sharing a common basic design, the 86EM running at 1500 rpm and the 100EM running at 1200 rpm, for 60Hz markets, Guascor Energy is the only one offering a direct drive solution for the 60Hz markets, avoiding the need of a gearbox and thus maximizing even more efficiency and simplifying installation and maintenance requirements.

The innovative approach for the endurance tests, using the RDS tool, and the exhaustive monitoring of the operation of the first units in the field has made it possible to complete the development of an engine with the highest reliability.