At the core of the decarbonisation path

The signing of the Paris Agreement by the 195 members participating in the Framework Convention on Climate Change (COP21) held in November 2015 marked a before and after in the global treatment of greenhouse gas emissions. Despite political and macroeconomic turbulences, commitment and the path to transformation continues even faster as planned.

The fundamental objective of the Agreement is to limit the increase in the global temperature of the planet to less than 2ºC compared to pre-industrial levels with the aim of achieving a planet with a neutral climate by the middle of this century. This ambitious goal can only be achieved by reducing the emission of greenhouse gases into the atmosphere as much as possible and requires the establishment of new decarbonisation strategies worldwide that allow the generation and use of energy with the least possible environmental impact.

Hydrogen, being a completely decarbonized vector, is present in all the decarbonization strategies that are being developed throughout the world. Hydrogen has become the main facilitator of the energy transition that must be carried out to achieve the established objective of reducing greenhouse gases. The use of hydrogen as an energy vector allows the decarbonisation of the currently most polluting sectors, including transport and mobility, industrial processes with a high energy demand and the generation of electricity. With regard to electricity generation, hydrogen allows the large-scale integration of intermittent renewable energy in the energy system, facilitating its distribution and storage, favouring the reduction or elimination of CO2 emissions produced by the use of fossil fuels. fossils.

In this global context of decarbonization, different roadmaps are being defined that establish the short-medium term objectives that will allow the achievement of the final emission target established for the year 2050. Among the most advanced is the European decarbonization strategy that, based on the use of hydrogen as an energy vector, it establishes three clearly defined implementation phases:

| 2020 – 2024 | • Decarbonise current hydrogen production for current uses, such as the chemical sector, and promote it for new applications.

• Installation of 6 GW of renewable hydrogen electrolysers. • Production of up to one million tons of renewable hydrogen. • Creation of hydrogen valleys by bringing together the entire H2 value chain in the same geographical area. • Use of the NG distribution network for distribution of H2 (mixture) in specific areas |

| 2025 – 2030 | • Installation of 40 GW of renewable hydrogen electrolysers

• Production of up to 10M tons per year of green hydrogen. • Use of the NG network to distribute NG mixtures with up to 20% H2, (90% network in Germany and Holland). • Specific distribution network for 100% H2 in specific areas, hydrogen valleys. • 55% reduction in greenhouse gases compared to 1990 values. |

| 2030 – 2050 | • Mature green H2 production technology.

• Large-scale deployment in all sectors that are difficult to decarbonise. • Independent high purity H2 distribution network. • 32% by volume of NG replaced by H2 in 2040. • 100% carbon free fuels, of which 50% H2 in 2050. |

Guascor Energy Experience

Guascor Energy is not a stranger to the energy revolution that is taking place worldwide and works hard to develop new products and solutions that adapt to the new needs demanded by the power generation market.

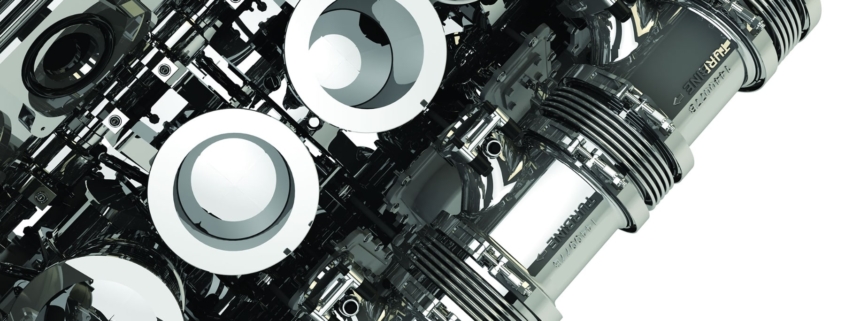

The experience of more than 50 years in the development and manufacture of internal combustion engines together with the extensive knowledge in applications with synthesis gases make Guascor Energy one of the main players in the field of electricity generation based on hydrogen as gas.

In this sense, Guascor Energy has a product line specifically designed to work with synthesis gases with a high hydrogen content (up to 40%). The extensive experience demonstrated over more than 20 years of work with synthesis gases has allowed Guascor Energy to establish a clear line of work to develop a new product line exclusively designed and optimized for applications in which hydrogen is used. As fuel.

The current configuration of Guascor Energy natural gas engines allows the use of natural gas mixtures with up to 15% hydrogen as fuel while maintaining engine performance in terms of power generated. Likewise, small changes in the natural gas engine configuration allow it to work with up to 50% hydrogen, slightly penalizing the performance provided compared to the natural gas reference.

Taking the engine configuration for natural gas as a starting point, Guascor Energy works on improving the internal configuration of the engine, optimizing both the chamber and the combustion cycle to obtain the best performance in both power and performance when the fuel used is a mixture of natural gas with 20% hydrogen. In order to provide service to all customers with natural gas engines currently installed in the field that wish to operate with hydrogen mixtures as fuel, Guascor Energy is working simultaneously on the creation of the necessary adaptation kits for this new operation.

Guascor Energy Engines’ line of work is completed with the development of the 100% hydrogen engine based on the latest technologies available both in the field of combustion and in the specific materials of the components in contact with hydrogen used in the engine.

Applications

Despite the fact that hydrogen-based electricity generation is being considered secondary in most decarbonisation strategies since priority is found in the mobility and transport sectors, it is true that the use of hydrogen in cogeneration applications It is presented as a solution to reduce emissions in segments that are difficult to electrify, with a high thermal demand or with limited access to conventional energy sources (isolated areas). It is in these applications where the use of the internal combustion engine is of special interest and it is where Guascor Energy is putting all its attention, optimizing its gas engines so that, adapting to customer needs, they provide the best performance with the new fuel. .

Guascor Energy is a leading company in the manufacture of both diesel and gas internal combustion engines for all types of industrial and marine applications. Headquartered in Zumaia (Guipúzcoa), it has a leading R&D centre in the Álava Technology Park where it develops the best solutions demanded by the current power generation market.