Gen-sets for Lamar City Landfill

Benefits

The Opportunity

The City of Lamar is located 110 miles south of Kansas City in southwestern Missouri. Lamar is best known as the birthplace of President Harry Truman and the town where Wyatt Earp first worked as a constable. With a population of 4,500 people whom embrace a small town way of life, Lamar is a quintessential picture of the American heartland.

What makes Lamar unique for a community of its size is that it remains on the cutting edge of energy technology and environmental responsibility. The town owns and operates a waste-to-energy plant at its municipal landfill and exports power to 2,000 homes in the city.

The Lamar landfill accepts approximately 1,650 tons per day of predominately municipal solid waste (MSW) from a six-county area.

The primary sources of the MSW are residential, institutional and light commercial waste.

In 2010, the landfill installed two 1.6 MW gas engines to run on the methane produced by the waste stored in the landfill. Due to ongoing landfill expansion, there was enough additional landfill gas (LFG) produced to fuel two additional reciprocating gas engines.

The Solution

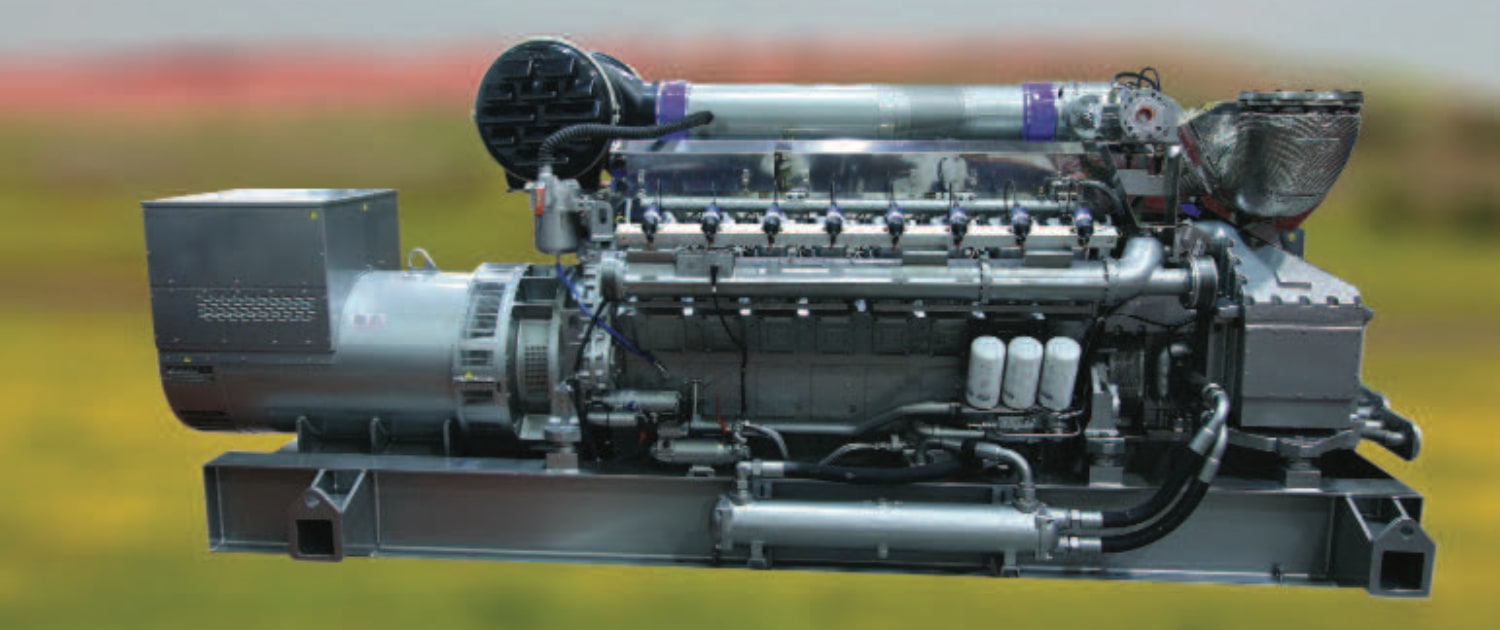

After careful evaluation and analysis of potential engine generator options — including existing gas engine generator sets operating at the site — the City of Lamar selected Martin gen-sets Machinery to install two of Guascor Energy’s LFG-fired G-56HM gen-sets, each rated at 1,350 kW, to produce the additional high-efficiency power needed.

Robustness, fuel flexibility and efficiency of the Guascor Energy engines, coupled with improved service and support capabilities of Martin Machinery, were key factors in Lamar’s decision to install Guascor Energy engines.

The maximum hourly heat input rate is 11.2473 million British Thermal Units per hour (MMBtu/ hr) each (3,295 kW per hour). With a fuel heating value of 479 Btu/ scf (505 kJ/nmc) for the LFG, the amount of LFG combusted by the engine at 100% loading is calculated to be 0.02348 mmcf/hr (664.48 nm /hr).

These engines have averaged 97% availability since being commissioned. Engine performance, as well as support and service provided by Martin Machinery, have exceeded the town’s expectations.

The Business

Guascor Energy is a leading company with more than 50 years of experience in the design and manufacture of diesel and gas internal combustion engines with its own technology. The company offers some of the most efficient and environmentally friendly technology platforms, products and services in distributed power generation for oil and gas, industrial, institutional, commercial clients and rural electrification programs. In addition, our offer is completed by a range of diesel engines for marine applications for both propulsion and on-board generation.

A complete product range which meets the strictest regulatory and safety requirements always adapting to the customer´s needs.

Guascor Energy has a network of more than 50 distributors and partners worldwide, which in addition to our own staff, allows us to provide unparalleled proximity and respond to the specific needs of each of our customers at a fast and personalized pace.