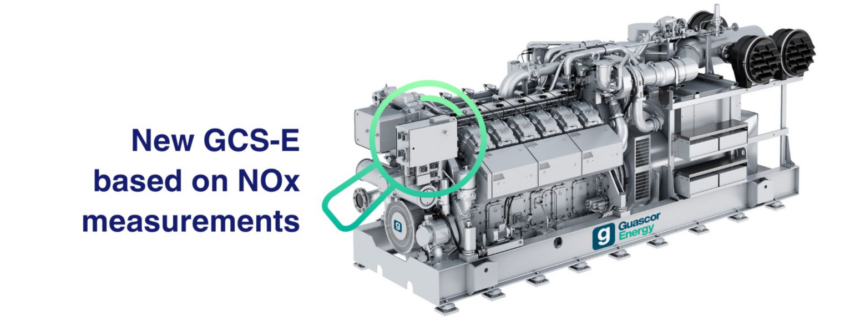

Meet our new GCS-E based on NOx measurements

At Guascor Energy we always go one step further to offer the best products and services to our clients. That is why we introduced our own Control Systems GCS to all our engines and we offer them also for gensets and plants.

The control system is the brain of the engine, is the one that tells the engine what to do, when and how to ensure the best performance and a completely safe operation.

The Guascor Energy GCS is a technologically advanced system that allows you to control and monitor your plant, while maximizing equipment efficiency. It comprises the whole engine parameters control and the alarms management and also includes a unique diagnostics and trending software. The GCS concept significantly reduces complexity reducing integration costs.

The GCS-E governs the engine unit, controlling among others carburation, ignition, speed and load control and protections. It is a plug and play system that simplifies installation and commissioning.

The GCS-G governs the genset unit, controlling among others the alternator, synchronization, power output and peripherals. Applicable to any range of frequency and voltage, it controls up to 3 gen-sets working together, in island and sharing load, being also able to control the plant grid switch.

The GCS-P governs the different elements of a power plant, it governs the GCS-G units, operation of the grid switch and additional ancillary operations. It controls the GCS-G when more than 3 gensets operate in island mode or a complex installation is required.

Now Guascor Energy is about to release a new engine control algorithm for the GCS-E based on NOx emissions direct measures.

The advantages of this new control include:

- Greater stability of emissions over time.

- Improved start-up and service times due to the possibility of self-carburation.

- Improved engine operation by ensuring correct carburetion.

- Improved diagnosis and protection by using the NOx signals.